Malt House Automation Case Study

Double Eagle Malt, Huntingdon Valley PA

Vortechs designs and builds Pennsylvania malt house automation system with room to grow with the business.

Double Eagle Malt is a Pennsylvania malt house located in Huntingdon Valley, processing barley and other grains into malt, which they then sell to craft brewers and distillers to turn into beer and spirits. Their objective is to support local farmers and local brewers in choosing more sustainable, shorter supply chains, while also celebrating the variety and variability that are only found in local grain varieties and grown under various unique regional farm conditions, what is known as terroir.

A seeming paradox of their endeavor is that while the purpose of the malt house is to champion the variability that comes from local brewing with local grain, they want to minimize variability in their malting process itself. They want variation in character, but consistency in quality.

The malting process involves steeping -- soaking grain in water until it "thinks" it has been planted and begins to germinate. When this happens, enzymes in the grain are developed and begin to dissolve the protein that encases the starches making it accessible for brewers to convert into simple sugars that will eventually become alcohol. Before that growth can happen, however, the maltster halts the process by kilning -- heating and drying the grain to preserve it at peak sugar extract potential and develop unique flavors . The whole process takes nearly a week, and temperature and moisture must be monitored and controlled throughout. At targeted points in the process, the entire bed of grain must also be turned to prevent clumping and ensure even drying.

"Choosing a process control company can be daunting. They range from too-small individual freelancers up to too-large multinational corporations. Double Eagle was fortunate to find Vortechs Automation right in the Goldilocks zone, experienced enough to offer us the solutions we need, and flexible enough to meet us where we were at."

-- Alan Gladish, Double Eagle Malt Business Manager.

As a new business, automation of the malting systems was piecemeal and incremental by design.

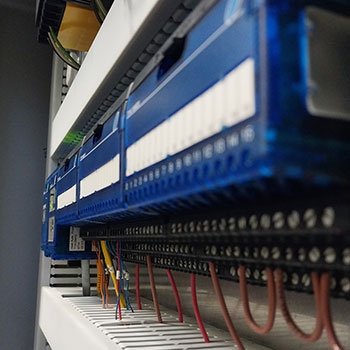

The first batch, in their 1,500-lb Steep, Germination, Kilning (SGK) vessel fabricated from a repurposed dairy storage tank, had an I/O list of just 4 sensors, a motor, and a heater, but they had larger ambitions. As a process control company, Vortechs Automation is accustomed to accommodating the incremental growth of a customer's process.

For this reason, a PLC that accommodates expansion modules was chosen to allow plenty of room not just for additional I/O for one malting vessel, but also for expanding to add entire additional systems. And expand they did.

Double Eagle now has a second system with nearly ten times the capacity of their initial 1,500-pound batch SGK, which is also still in service. In the large system, turning the grain by hand like they do with the small SGK is impractical. Instead, the system was designed as a rotating drum to be loaded with a pump and unloaded with an auger into a powerful vacuum grain handling system.

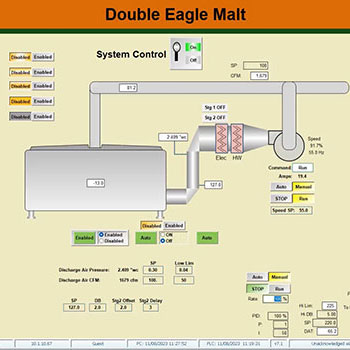

The malting process takes several days, and Double Eagle does not have the staff nor resources for round-the-clock on-site monitoring. Instead, Vortechs Automation created a PC based HMI that can also connect to the maltster's smartphone. This allows the maltster to not only read the system status remotely, but to even control the system remotely -- adjusting temperatures, moisture levels, and air circulation -- all from home. Many of the adjustments are automated, but the remote monitoring is also capable of issuing alerts for potential failure conditions such as power outages.

Some of the sensors must monitor temperature and humidity inside the malting drum, but at certain points in the process, the entire drum must rotate, creating wiring challenges for those drum-mounted sensors. The center point of the rotating drum already has concentric rotating fittings for water and auger-motor power. Vortechs avoided further complicating the wiring by using wireless sensors that deliver their signal to the PLC via a specialized transmitter/receiver.

The system does more than real-time monitoring and control. It also logs all the data from the system so the maltster can compare system conditions to quality control outcomes. The controls allow operators to enter custom control routines if they want to modify the sequence for specific grain conditions, for example.

Vortechs has also consulted and assisted with upgrades to other equipment not connected to malting controls -- retrofitting a grain mill with an automatic check-weigher, as well as technical support for the light curtain providing safety around the rotating drum.

Programable Logic Controller

Programable Logic Controller

Wireless sensors on germination/kilning drum

Wireless sensors on germination/kilning drum

SGK Control Screen

SGK Control Screen